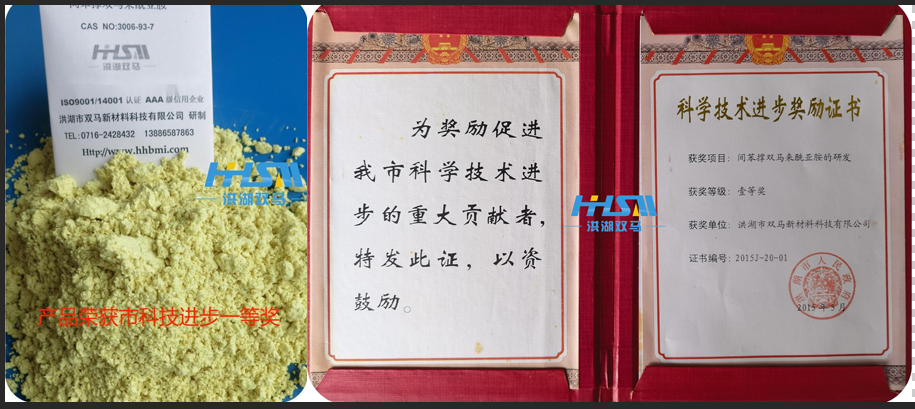

间苯撑双马来酰亚胺(PDM或HVA-2)

发布时间:2023-07-09 21:34:35点击:905

一、简介

中文名称:N,N’-间苯撑双马来酰亚胺 英文名称:N,N’-m-phenylene dimaleimide

简 称:PDM或HVA-2 分子式:C14H8N2O4 分子量:268

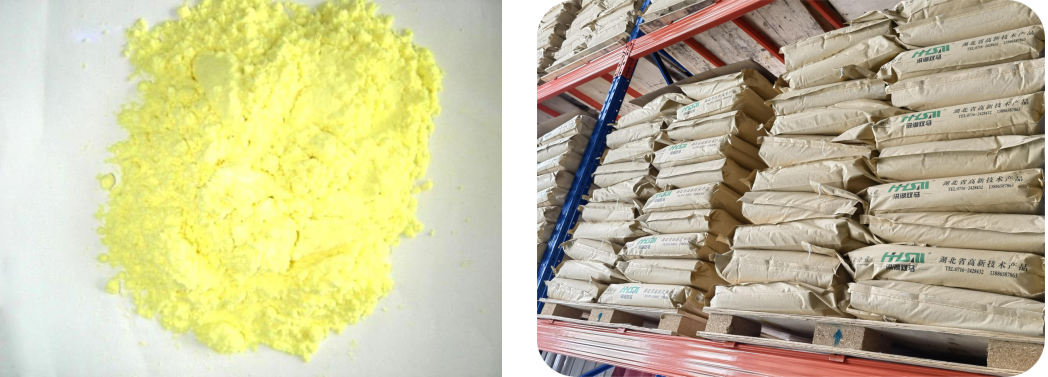

物化性质:黄色或棕黄色粉末,比重1.44,可溶于二氧陆环、四氢呋喃和热的丙酮中,不溶于石油键、二氯甲烷、四氯化碳、苯和水中。

CAS NO:3006-93-7

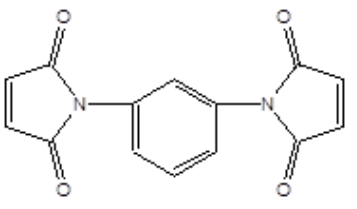

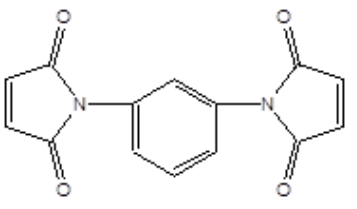

结 构 式:

二、技术指标

项 目 | 指 标 |

外 观 | 黄色粉末 |

含 量 | ≥99% |

熔点,℃ | ≥195℃ |

灼烧残渣,% | ≤0.5% |

加热减量,% | ≤0.3% |

酸值,% | ≤0.9% |

筛余物,325目 | ≤0.5% |

三、用途

N,Nˊ‐间苯撑双马来酰亚胺(也叫PDM或HVA-2),为多功能橡胶助剂,在橡胶加工过程中既可作硫化剂,也可以作过氧化物体系的助硫化剂,还可作为防焦剂和增粘剂,既适用于通用橡胶,也适用于特种橡胶和橡塑并用体系。

在天然胶中,与硫磺配合,能防止硫化返原,改善耐热性,降低生热,耐老化,提高橡胶与帘子线粘合力和硫化胶模量。用于载重轮胎肩胶、缓冲层等橡胶中,可解决斜交载重轮胎肩空难题,也可用于天然橡胶的大规格厚制品及各种橡胶杂品。

在氯丁橡胶、氯磺化聚乙烯橡胶、丁苯橡胶、丁腈橡胶、异戊二烯橡胶、丁基橡胶、溴化丁基橡胶、丙烯酸酯橡胶、硅橡胶和橡塑并用胶等特种橡胶中,作为辅助硫化剂,能显著改善交联性能,提高耐热性,适用于高温硫化体系,降低压缩永久变形十分明显,还能减少过氧化物的用量,防止胶料在加工过程中的焦烧,提高胶料和帘子线及金属的粘合强度。

PDM属无硫硫化剂,用于电缆橡胶,它可代替噻唑类、秋兰姆类等所有含硫硫化剂,解决了铜导线和铜电器因接触含硫硫化剂生成硫化铜污染发黑的难题。

四、包装

标准包装是纸塑复合袋,净重10KG或20KG或按客户要求包装.

贮存:在阴凉干燥处可存储两年.

Product Introduction

![]() PDM / HVA-2 / BMI-08 Applications

PDM / HVA-2 / BMI-08 Applications

HHSM:BISMALEIMIDE[PDM / HVA-2 /BMI-08]

N,Nˊ‐间苯撑双马来酰亚胺

HHSM:BISMALEIMIDE [PDM / HVA-2 /BMI-08]

1. Introduction

CHEMICAL Name: N.N´-m-phenylene dimaleimide

Abbreviation: PDM or HVA-2 BMI-08

Molecular Formula:C14H8N2O4 Molecular weight:268.22 CAS NO:3006-93-7

Structure Formula:

Physical and Chemical Feature:Yellow or brown yellow powder ,proportion: 1.44,it is dioxyide Lu Wan, , Fourth hydrogen Furan and hot acetone soluble,petroleum, dichloromethane, Fourth carbon chloride, benzene and water soluble.

2. Technology Index

Iterms | index |

appearance, | yellow powder |

melting point,℃ | ≥195℃ |

Burning residue,% | ≤0.5% |

the heating loss,% | ≤0.5% |

acid value | 1.0 mgKOH/g |

Screenings,325目 | ≤0.5% |

3.Use

Also called PDM or HVA - 2/bmi-08, multi-functional rubber additives, can be used in the process of rubber processing as vulcanizing agent, also can make peroxide system helps the vulcanizing agent, also can make antiscorching agent and tackifier, applies to general-purpose rubber, also applies to special rubber and rubber and system.

Cooperate with sulfur in natural rubber, can prevent sulfide to return the original and improved heat resistance, reduce the heat generated, ageing resistance.

Improve rubber and cord adhesion force and sulfide film.

Used in truck tire shoulder gum, rubber cushion layer.

Can solve the problem of oblique load tire shoulder empty.

Can also be used for large size thick products of natural rubber.

In chloroprene rubber, chlorosulfonated polyethylene rubber, styrene-butadiene rubber, nitrile rubber, isoprene rubber, butyl rubber brominated butyl rubber, acrylate rubber, silicone rubber and rubber and rubber and other special rubber, as auxiliary vulcanizing agent, crosslinking performance can be improved significantly, improve the heat resistance, is suitable for the high temperature fluidization system.

Reduce the compression permanent deformation is very obvious.

Also can reduce the dosage of peroxide, can prevent the rubber scorch in the process, improve and rubber tire cord and metal bonding strength

Dosage It can be used as anti-scorcher agent 0.5~1.0,as curiing agent 2~3,and improver agent 1.5,binder improver agent 0.5~5.0.

4.Packaging

10kg or 20kg(net weight),kraft bag inner PE coated or packaging according to customer's request.

5. Storage

This material can be stable for 24 months under the normal storage conditions.However,precautions must be taken to avoid exposure to sunlight and always ,store this material in a sealed container under the dry and cool conditions.

- 上一篇:没有了!

- 下一篇:没有了!